How do active pharmaceutical ingredient manufacturers produce?

The production process of active pharmaceutical ingredient (API) manufacturers mainly includes the following steps:

Raw material extraction: The first step in pharmaceuticals is to obtain active ingredients, which can be extracted from natural plants, animal tissues, or minerals. For example, extracting flavonoids from Ginkgo biloba leaves requires steps such as crushing, solvent soaking, filtration and concentration to ensure purity standards are met. Microbial fermentation is also an important method, such as using specific bacterial strains to produce antibiotics, which requires controlling parameters such as temperature and pH to optimize yield.

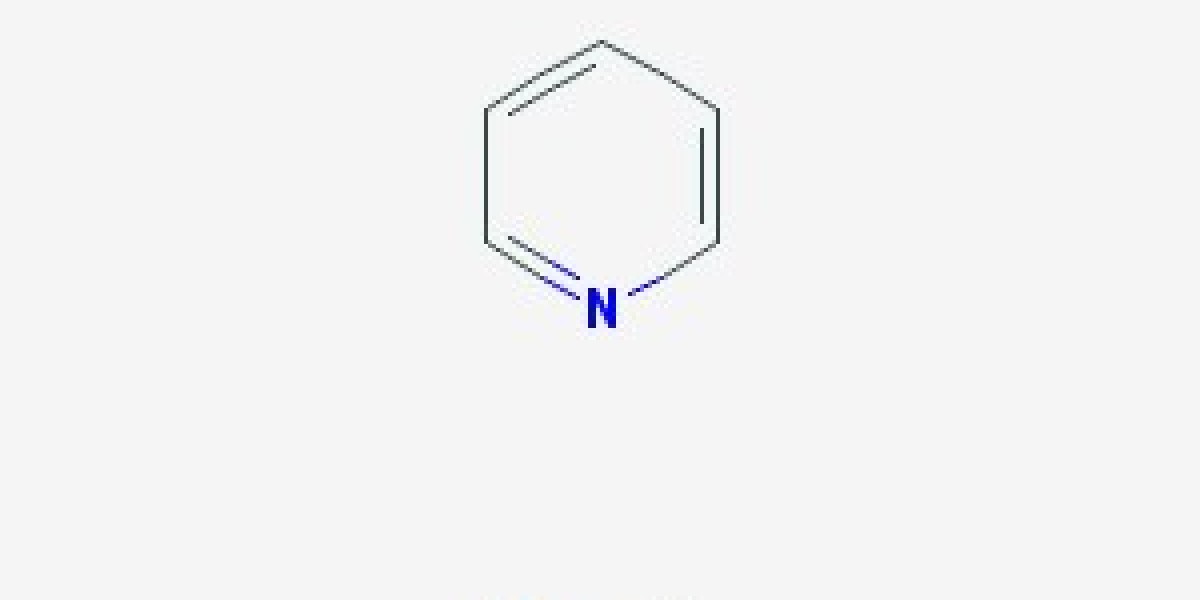

Component synthesis: Some drugs need to be obtained through chemical synthesis, such as aspirin, which is made from salicylic acid through acetylation reaction. Modern technology can design molecular structures and improve efficiency through reactions such as catalysis and condensation. Biological synthesis technology utilizes genetically modified cells to produce protein drugs, such as insulin, which requires precise regulation of expression conditions.

Formulation preparation: Process the active ingredients into a suitable form for use, such as tablets that require mixed excipients for compression, and injections that require sterile filling. The release speed of sustained-release formulations is controlled through coating technology, while the viscosity of the matrix needs to be adjusted for external plasters. Stability, absorption rate, and patient compliance need to be considered for different dosage forms.

Quality inspection: The finished product must comply with pharmacopoeia standards, including content determination, impurity detection, dissolution testing, etc. High performance liquid chromatography is used to analyze the purity of components, and microbial limit testing ensures sterility and safety. Stability test simulates long-term storage conditions to verify the validity period.

Clinical validation: The drug enters human trials after animal experiments and is evaluated for safety, efficacy, and dosage in three phases. Double blind controlled trials exclude subjective bias, and big data analysis is used to statistically analyze differences in therapeutic efficacy. After approval, adverse reactions still need to be monitored and medication plans need to be improved.

Specific case analysis:

Haixiang Pharmaceutical has applied for a patent for a continuous production method of clindamycin hydrochloride. The steps include preparing a solution of triphosgene in DMF, a solution of lincomycin or its hydrochloride in chloroform, and then pumping these solutions into a reaction plate at a certain flow rate for reaction. Finally, after post-treatment, clindamycin hydrochloride is obtained.

United Deyi has developed a new generation of spray drying technology that can achieve instant drying while maintaining peptide activity and meeting customer requirements for particle size and moisture, demonstrating its technological innovation in API production.